Introduction

This guide is tailored for company purchasers and startups venturing into the license plate manufacturing industry.

It covers the entire manufacturing process, material choices, design specifications, and the machinery involved, providing a thorough understanding necessary for setting up or optimizing a license plate production line.

What Are License Plates Made Of?

License plates are primarily crafted from aluminum due to its durability, lightweight nature, and ease of embossing. The aluminum is often pre-cut and treated with a reflective film lamination to ensure visibility and compliance with road safety standards.

This base material may be further enhanced with high-quality inks and protective finishes to withstand varying weather conditions and extend the plate’s longevity.

Where Are License Plates Made?

Globally, license plates are manufactured in a variety of settings, ranging from state-run facilities to private companies.

In the United States, about 80% of all license plates are produced by state prisoners. However, many other countries outsource production to specialized private firms that comply with national standards and regulations.

How Are License Plates Generated?

This assembly is then stamped to raise the characters, which are inked for enhanced visibility. A protective coating is applied to preserve the plate’s integrity against environmental factors.

This method is standard in many countries, adapting to local regulations concerning material and design.

Where Do License Plates Come From?

In the U.S., license plates are issued by state Departments of Motor Vehicles (DMVs) or similar agencies.

Globally, the responsibility varies: in some countries, it’s handled by national governments, while in others, local or regional authorities oversee plate issuance.

Native American tribes in the U.S. and similar indigenous groups in other nations may also issue their own registration plates.

License Plate Machines

The machinery used in the production of license plates is specialized and designed for mass production.

These machines perform a variety of tasks such as cutting, embossing, painting, and curing.

Cutting machines cut the aluminum into plate-sized sheets. Embossing machines then raise the numbers and letters on these sheets. After embossing, the plates are painted for visibility and protection against the elements. Finally, a protective coating is applied to prevent fading and wear.

License Plate Material Selection

The choice of material is fundamental in determining the quality, cost, and environmental impact of license plates.

Aluminum

- Durability: Aluminum’s high strength and corrosion resistance make it an ideal choice for durable license plates.

- Longevity: Perfect for regions with harsh weather conditions, ensuring the plates last for many years without significant wear.

Reflective Sheeting

- High Security: The reflective sheet material will be coated on the surface of the aluminum sheet. It will help to increase the reflectivity of the aluminum panel as well as increase the safety of the aluminum panel surface.

Design and Layout

The design of license plates is a critical factor that marries aesthetic appeal with compliance to legal standards.

Color and Graphics

- Identity Representation: Colors and graphics not only help in vehicle identification but also promote the jurisdiction’s identity through distinctive designs.

- Visibility and Recognition: Bright and reflective colors are chosen to ensure plates are visible both day and night.

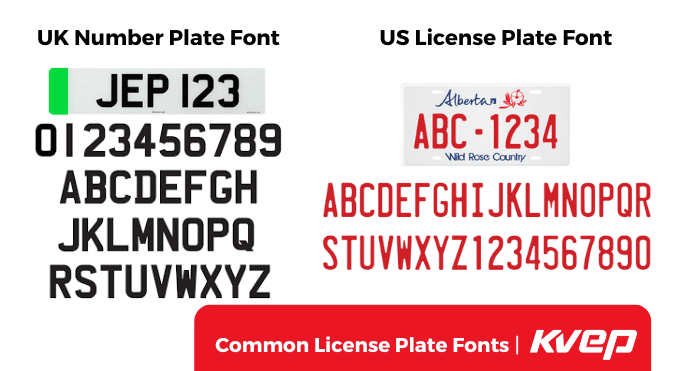

Font and Size

- Standardization: Fonts are chosen for their clarity and difficulty to replicate, which helps in preventing plate forgery.

License Plate Layout

- Regulatory Compliance: Layouts are designed to meet specific state or national standards, which include the placement and spacing of characters.

License Plate Security Features

- Anti-Counterfeiting: Modern plates may incorporate features like RFID chips, barcodes, or unique identifiers that make them difficult to counterfeit.

How to Make License Plates

The process of making license plates involves several detailed steps:

License Plate Blanking (Include Lamination & Cutting)

The process begins with the creation of plate blanks from selected materials.

Cutting Machines

- Precision Cutting: High-tech machinery ensures that each blank is cut to exact dimensions required.

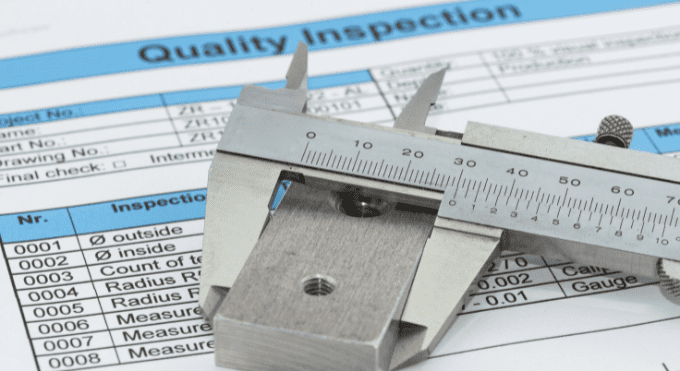

Quality Control

- Inspection: Each blank undergoes rigorous inspection to ensure compliance with quality standards before moving to the next stage.

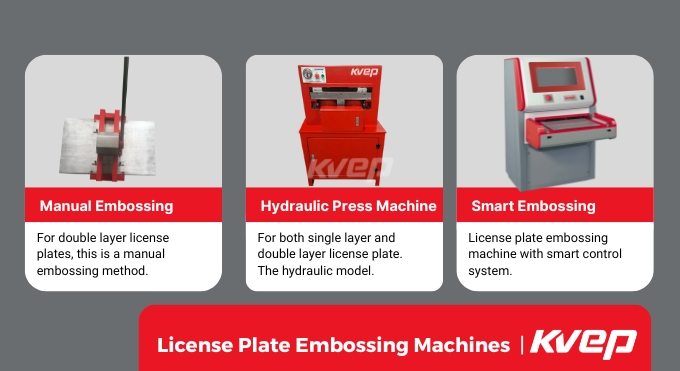

License Plate Embossing

Raised characters are formed on the blanks through embossing, which enhances both the aesthetic and functional aspects of the plates.

Hydraulic Presses

- High Pressure: Uses intense pressure to create clean, precise embossed characters.

Qualification Checks

- Precision: Ensures that all characters are correctly aligned for uniformity across all plates.

- Defect Checks: Each embossed plate is checked for defects to ensure only the highest quality plates are painted and finished.

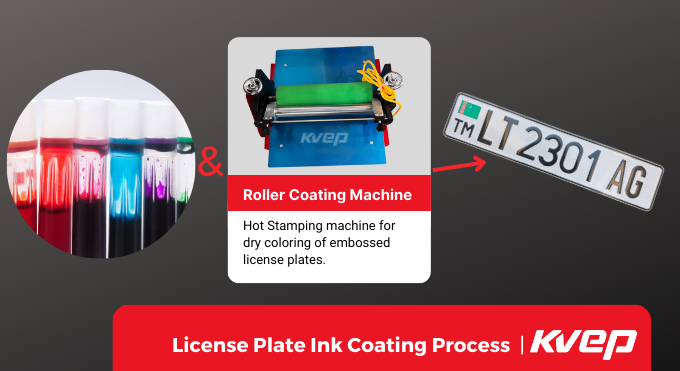

License Plate Coloring

Coloring involves steps to achieve the final design and ensure durability.

Ink Coating

The process is usually finished by the ink roll coaters.

- Base Layer: A primer is applied to enhance the adhesion of subsequent paint layers.

- Color Accuracy: Multiple layers are applied to match the exact colors specified in the design.

Curing and Drying

- Set and Seal: The ink is cured in controlled conditions to ensure it sets properly without smudging or running.

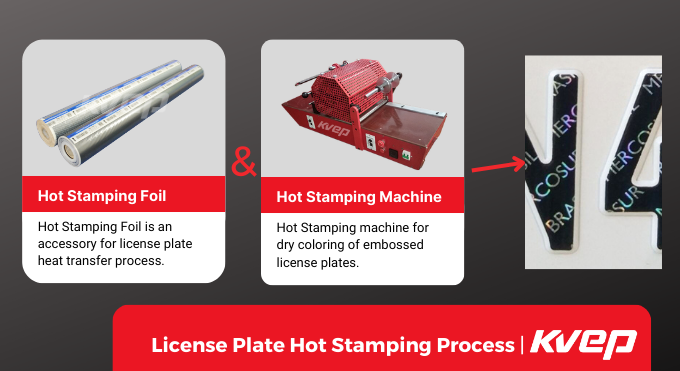

Hot Stamping

Hot stamping is the process of heat transferring ink from a hot stamping foil to the surface of embossed plate numbers and borders.

License Plate Types

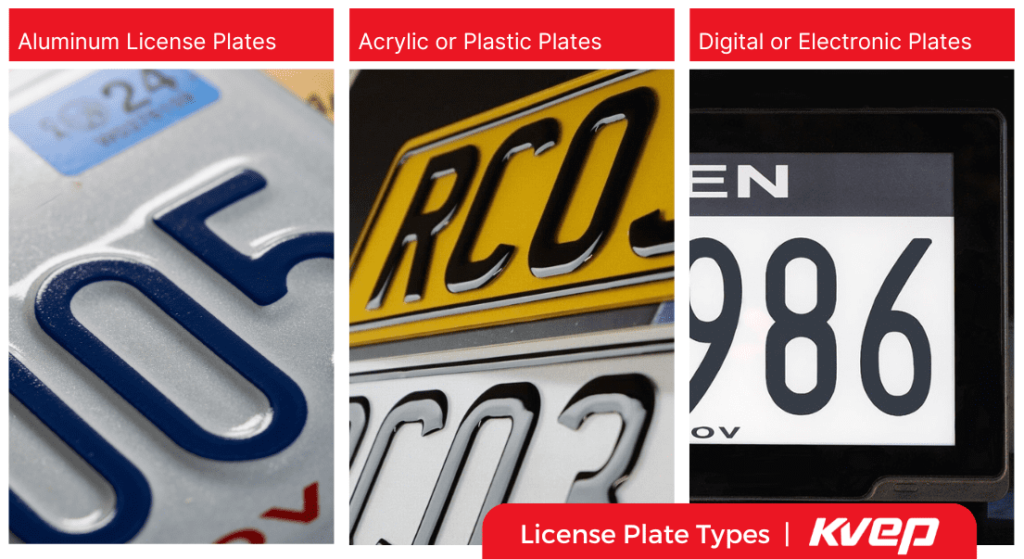

Based on Material Differences

License plates can vary significantly in the materials used, which affects their durability, cost, and application:

- Aluminum License Plates: The most common due to its light weight and resistance to corrosion. These are used globally and are suitable for most standard vehicles.

- Acrylic or Plastic Number Plates: These are lighter and can be less expensive than metal plates, used often in regions with lower budget or less harsh environmental conditions.

- Digital or Electronic Plates: Emerging technology allows for digital displays that can change information dynamically, used primarily in high-tech zones or testing environments.

Based on Application Differences

- Standard License Plates: The most common type, issued for personal and commercial vehicles.

- Personalized License Plates: Custom plates that allow for personalized number and letter combinations.

- Specialty License Plates: These plates support causes, institutions, or professions, often with distinctive designs and themes.

- Temporary License Plates: Issued for short-term use, usually made of paper or lightweight materials.

- Commercial License Plates: Designed for trucks and vehicles engaging in commerce, often bearing different color schemes or tags.

- Government License Plates: Issued for government vehicles, identifiable by unique colors and emblems.

Summary

In conclusion, the manufacturing of license plates is a complex process that involves specific materials and sophisticated machinery. Each step is crucial in ensuring that the license plates meet the required standards of durability, visibility, and regulatory compliance.