What is the new British Standard Number Plate?

BS AU 145e is the new British Standard Number Plate and represents the latest specification and requirements for vehicle number plates in the UK.

The BS AU 145e standard is designed to improve the durability and visibility of license plates to withstand harsher conditions.

Standard BS AU 145e number plate designs

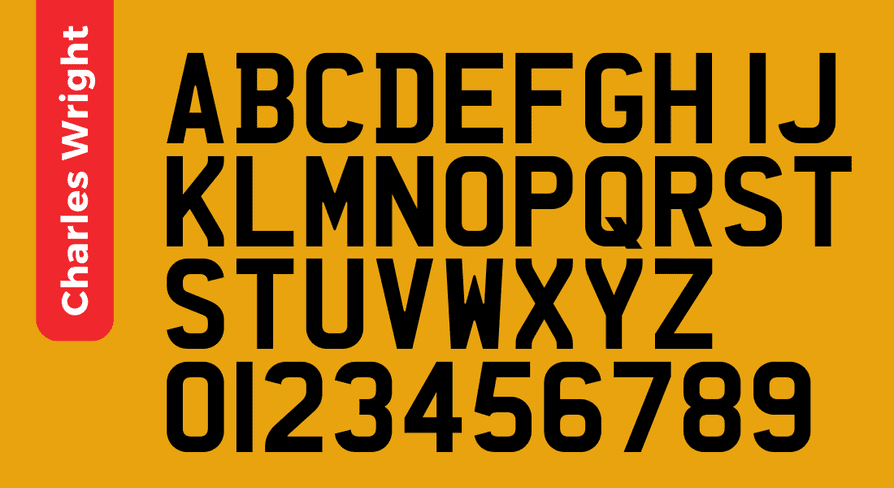

Charles Wright Typeface

The digit sizes is 79mm(height) x 50mm(width), stroke is 14mm.

Single Shade of Black Digits

The digit shall be one shade of black, can’t mix matt black digits and shiny black digits on same plate.

Correct Spacing

Spacing between characters: 11mm

Spacing between digit Groups: 33mm

Digit Shape Format Types

2D Print

3D Gel

4D Acrylic

Pressed Metal

Correct Plate Size

Standard oblong plate size: 520x 111 mm

Lipped plate size: 520x 125 mm

The minimum distance between digits and the plate edge should be at least 11mm.

Correct Materials

The number plate material must confirm to BS AU 145e testing for the reflective, digits and acrylic materials.

White front plate, yellow rear plate.

No background pattern.

No tinted materials.

Clear Supplier Details

Inlcuding supplier name and postcode that registered with DVLA’s Register of Number Plate Suppliers.

Permanent 3D and 4D characters

The digits must not fall off the number plates.

ANPR Camera Readable

Whether which material the plates are made of, they need to be ANPR Camera friendly.

Legal Markings

Flag designs

- Union Jack

- Cross of St George

- Cross of St Andrew

- Red dragon of Wales

Badage Colors

- Common vehicles: blue badge

- Electric vehicles: green badge

National identifier letters

- UK;

- ENG;

- SCO;

- CYM;

- GB;

Please note: When you are driving overseas, you will need to display an additional UK sticker with GB national identifier.

BS AU 145e:2018 Testing for License Plates

If you’re considering getting your number plates tested to meet this standard, here’s what you need to know based on insights from an accelerated weathering laboratory.

BS AU 145e Investment and Costs

Testing your number plates according to the BS AU 145e:2018 standard involves a significant investment. The initial cost for testing is approximately £14,000.00 + VAT.

It’s important to note that if you have more than one type of plate construction to be tested, the costs will increase, although not proportionally.

BS AU 145e Material Specifications

The type and placement of materials in your number plates are critical factors in the testing process. Specifically:

- Reflective Material Placement: You need to specify whether the reflective material is placed above or below the acrylic layer.

- Backing Material: If the reflective material is above the acrylic, you must also indicate whether the backing of the number plate is plastic or metal. For metal backings, it’s essential to state whether the digits are pressed.

- Digit Style: If you require 3D or gel digits on your number plates, this must be included in the testing project.

Sample Requirements of BS AU 145e

To proceed with the testing, you need to provide sample units. The minimum requirement is six samples (one front and one rear). However, it is recommended to provide ten samples to account for contingencies.

The samples must be printed according to figure 1 of the BS AU 145e:2018 standard, which includes specific design elements like B8 and a black square.

BS AU 145e Testing Process and Timeline

The testing process is rigorous and involves multiple steps:

- Initial Testing and UV Weathering: The UV weathering test, as per clause 15 of the standard, requires an exposure period of approximately 2275 hours, translating to about 3.5 months.

- Colour and Retro-reflection Retesting: After the UV weathering test, the samples are retested for colour and retro-reflection to ensure they still meet the standard.

The entire process, from the receipt of your samples to the final certification, typically takes a minimum of 4 to 4.5 months.

Collaboration and Certification

The testing and certification process is a collaborative effort between LUX-TSI and the accelerated weathering laboratory. If your number plates meet all the necessary criteria after testing, a Certificate of Conformity (C of C) is issued.

FAQ

What is a BSAU 145e number plate?

BSAU 145e is the current UK number plate standard, replacing the previous BSAU 145d standard. The standard outlines the technical and performance requirements that number plates must comply with, including material durability, reflectivity and weathering resistance.

What is the difference between BSAU 145D and BSAU 145e?

BSAU 145e has more stringent requirements in the following areas:

Material quality: The signs must be made of more durable materials that can withstand greater environmental stress.

Reflectivity: Improved reflectivity standards ensure that license plates are more visible in all light conditions.

Abrasion Resistance: Increased resistance to abrasion, impact and environmental factors such as UV and UV radiation.